Precise Production and Manufacturing

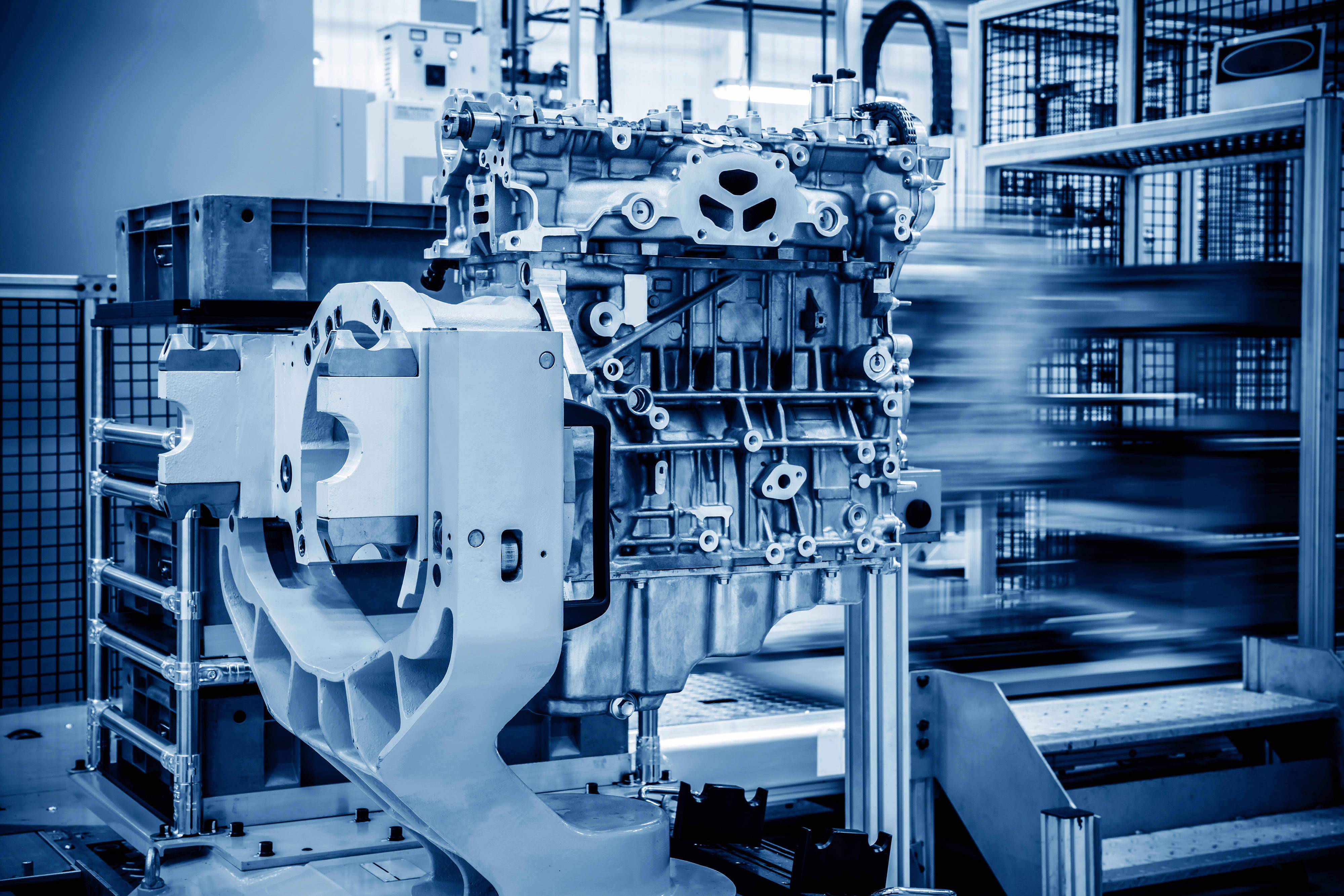

· Advanced Production Equipment:

We are equipped with a series of advanced production equipment for rubber sealing parts, such as high-precision injection molding machines, vulcanizing machines, extrusion machines, etc., enabling a fully automated production process from rubber mixing, molding to vulcanization. These equipments possess high-precision processing capabilities and stable production performance, ensuring that each customized rubber sealing part can meet strict dimensional accuracy and quality standards.

· Strict Quality Control System:

During the production process, we have established a complete quality control system. From the inspection and warehousing of raw materials to the factory inspection of finished products, every link is strictly controlled for quality. We adopt a variety of advanced testing equipment and methods, such as hardness testers, tensile testing machines, aging test chambers, leakage testers, etc., to conduct comprehensive tests on the physical properties, chemical properties, sealing performance, etc. of the rubber sealing parts, ensuring that the product quality complies with international standards and the personalized requirements of customers.