Mob/WhatsApp

.png)

+86 172 7861 3980

-

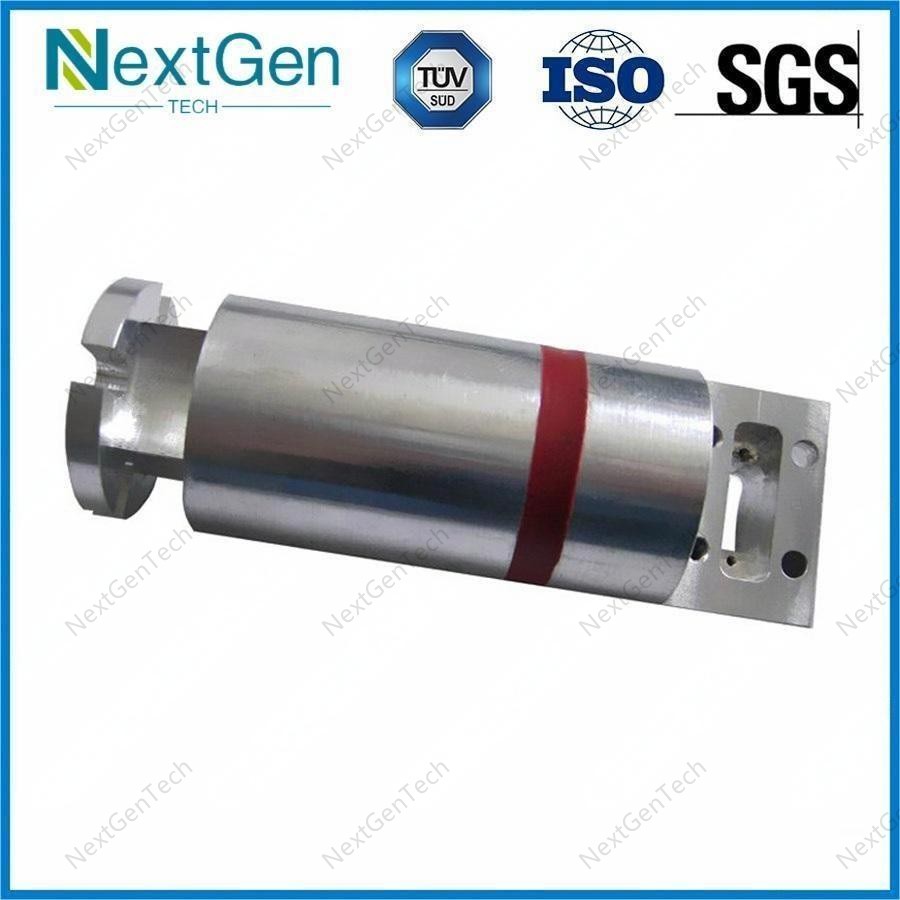

Rubber shock absorber

-

0.000.00

-

General Introduction

This advanced shock absorber is an essential part of the drilling equipment, aiming to address the challenges posed by vibrations and shocks during the drilling process. It is engineered to protect MWD and LWD instruments from the harsh drilling environment, ensuring their stable and accurate operation, thereby improving the overall efficiency and quality of drilling operations.

Working Principle

Vibration Energy Absorption: During drilling, vibrations are inevitable. The shock absorber's internal structure and materials are designed to deform or move relatively when vibrations occur. This converts the mechanical energy of vibrations into other forms, such as heat, thus reducing the amplitude of vibrations transmitted to the MWD and LWD instruments.

Impact Buffering: Through elastic elements or hydraulic systems, the shock absorber cushions the impact forces generated during drilling, preventing sudden high impacts from damaging the instruments.

Structural Design

Outer Casing: Typically made of high-strength alloy steel, the casing offers excellent wear resistance and corrosion resistance, enabling it to withstand the high pressure and harsh conditions in the drilling environment.

Damping Elements: Comprising springs, rubber pads, hydraulic cylinders, etc., the shock absorber selects an appropriate combination of damping elements based on different design requirements and working conditions to achieve the best damping effect.

Connecting Parts: These parts ensure reliable connections between the shock absorber, drilling equipment, and MWD/LWD instruments. High-precision threaded connections or other specialized connection methods are used to prevent loosening or detachment under high-vibration conditions.

Technical Features

High Damping Performance: It can effectively reduce various vibration frequencies and amplitudes during drilling, providing a stable working environment for MWD and LWD instruments and ensuring the accuracy of measurement data.

Wide Frequency Damping: Capable of absorbing and buffering vibrations of different frequencies, it adapts to the complex and variable vibration situations during the drilling process.

High Pressure and Temperature Resistance: With special materials and sealing structures, the shock absorber can operate normally under high-temperature and high-pressure drilling conditions, meeting the needs of complex drilling operations such as deep wells and ultra-deep wells.

High Reliability: Having undergone strict quality inspection and testing verification, it has high reliability and stability, reducing the risk of drilling accidents and instrument damage caused by shock absorber failures.

Application Advantages in MWD and LWD

Improved Measurement Accuracy: By reducing the interference of vibrations on instruments, MWD and LWD instruments can measure wellbore trajectory, formation parameters, and other information more accurately, providing more reliable data for drilling operations.

Extended Instrument Life: Effectively protecting MWD and LWD instruments from vibration and impact damage, it extends the service life of the instruments and reduces drilling costs.

Enhanced Drilling Efficiency: A stable working environment for the instruments helps to reduce drilling interruptions and adjustments caused by instrument failures or inaccurate data, improving the continuity and efficiency of drilling operations.

Application Cases

- In offshore deepwater drilling platforms, the MWD and LWD systems equipped with this advanced shock absorber can work stably under harsh ocean environments and complex geological conditions, providing accurate real-time data for drilling operations and ensuring the quality and safety of the wellbore.

- In onshore deep well drilling projects, this shock absorber effectively solves the problem of strong vibrations during drilling, improves the reliability and measurement accuracy of MWD and LWD instruments, reduces downtime due to instrument failures, and increases drilling efficiency.

Service Hotline

+86 172 7861 3980

WhatsApp:+86 17278613980

mail:alfred@nextgen-tec.com

Add: No. 733 Huangpu East Road, Huangpu District, Guangzhou,Guangdong,China

Guangzhou NextGen Technology CO.,LTD

NextGen Tech, focusing on sealing technology, with excellent strength and reputation in the field of rubber and plastic seals, metal seals and mechanical equipment parts.

+86 172 7861 3980

Contact Information

Mob:+86 172 7861 3980

WhatsApp\WeChat:+86 172 7861 3980

Email:alfred@nextgen-tec.com

Add: No. 733 Huangpu East Road, Huangpu District, Guangzhou,Guangdong,China

Product Category