Mob/WhatsApp

.png)

+86 172 7861 3980

Release the system pressure first, and then disassemble the hydraulic components related to the sealed pressure chamber.

Prepare oil collection devices to collect the outflowing oil.

Disassemble and decompose hydraulic components in a clean place to prevent dust from mixing in during assembly.

Do not use excessive force when disassembling, decomposing, and assembling hydraulic components to avoid damaging them.

Pay attention to the assembly relationship of each part inside the hydraulic component to avoid assembly and installation errors. Some mating parts (such as the plunger and cylinder bore of an axial piston pump) need to be selected, and it is necessary to ensure that the reassembly is consistent with the original assembly relationship.

Disassembly and Inspection of Pump Components

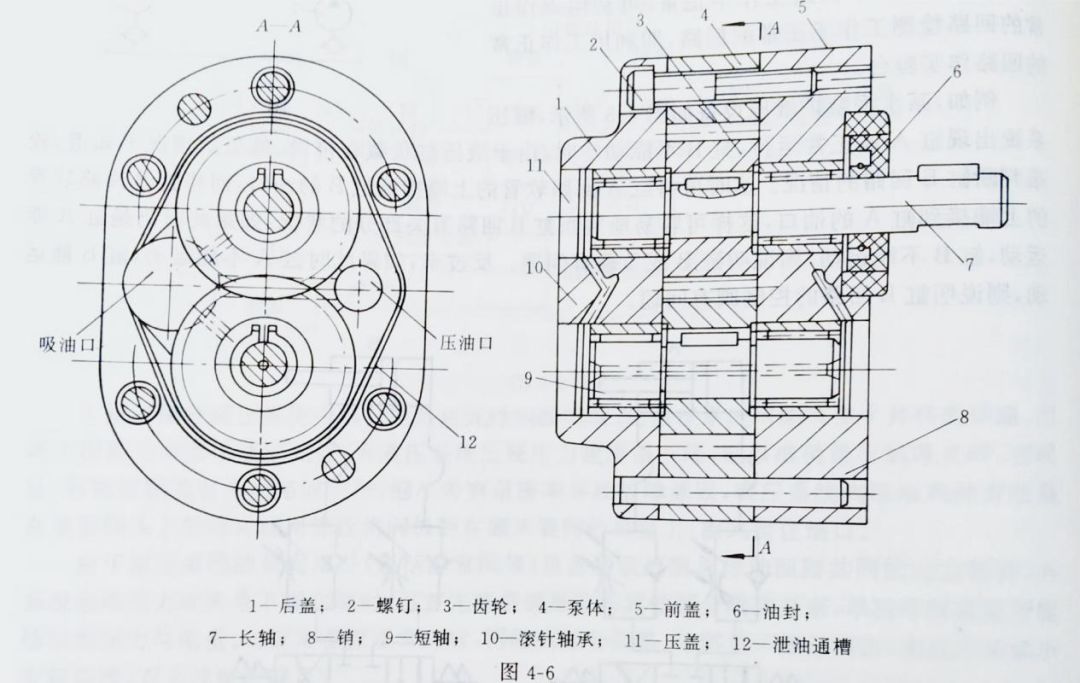

Disassembly, Decomposition, Observation and Testing of Gear Pumps. The structure of the CB-type gear pump is shown in Figure 4-6. When disassembling the gear pump, the following aspects of the pump can be inspected:

(1) The wear condition of the front and rear end covers of the pump.

(2) The wear condition of the gear end faces.

(3) The wear condition between the tooth tips and the pump casing.

The above-mentioned wear parts are related to the internal leakage and temperature rise of the pump, as well as the decrease in pressure and flow.

(4) The fracture condition of the pump shaft, which is related to the lack of oil supply.

(5) The wear condition of the bearings, which is related to the pressure fluctuation and the increase in noise.

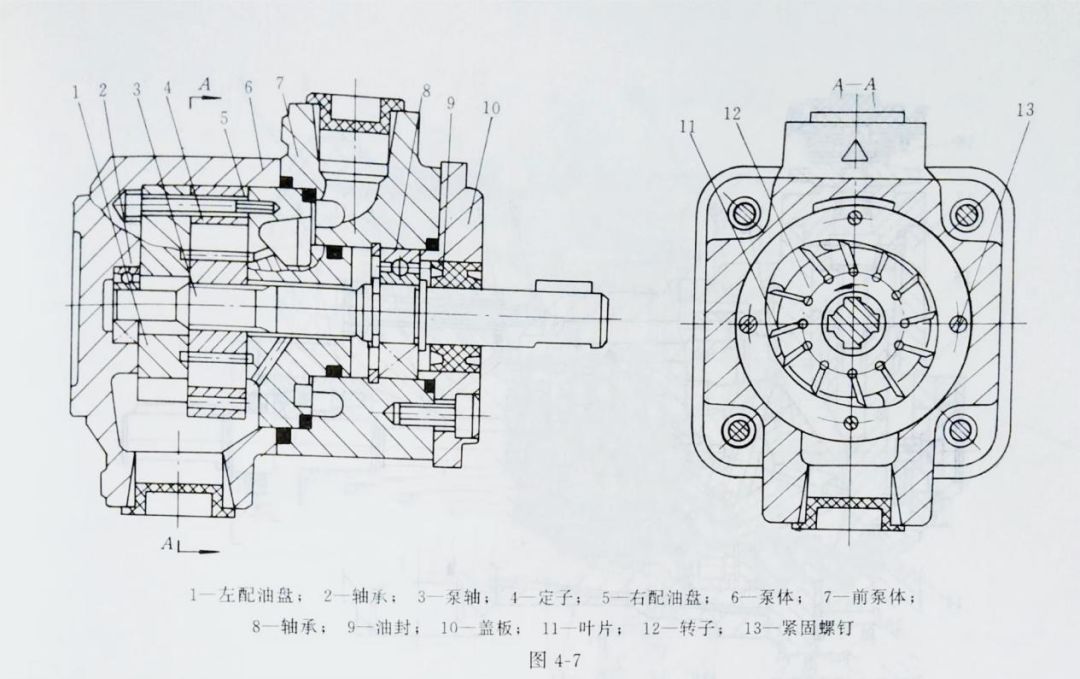

(6) The damage condition of the seals, which is related to external leakage.Disassembly, Decomposition, Observation and Testing of Vane Pumps. The structure of the YB1-type vane pump is shown in Figure 4-7. When disassembling the vane pump, the following aspects of the pump can be inspected:

(1) The wear condition of the inner curve of the stator.

(2) The wear condition of the distribution plate.

The above situations are related to the decrease in output flow and pressure, the increase in internal leakage, component heating, etc., and are also related to the increase in pressure fluctuation.

(3) Whether the installation direction of the rotor is correct, which is related to the increase in noise.

(4) The wear condition of the rotor end face and the wear condition of the rotor vane slots, which are related to the increase in internal leakage.

(5) Whether the rotor is fractured, which is related to the decrease in flow and pulsation, and is also related to the increase in noise.

(6) Whether the vanes are stuck in the vane slots, which is related to the decrease in flow and pulsation.

(7) The wear condition of the vanes, which is related to the increase in noise.

(8) The wear condition of the bearings, which is related to the increase in noise.

(9) The wear condition of the seals, which is related to external leakage.

(10) Whether the shaft is fractured.

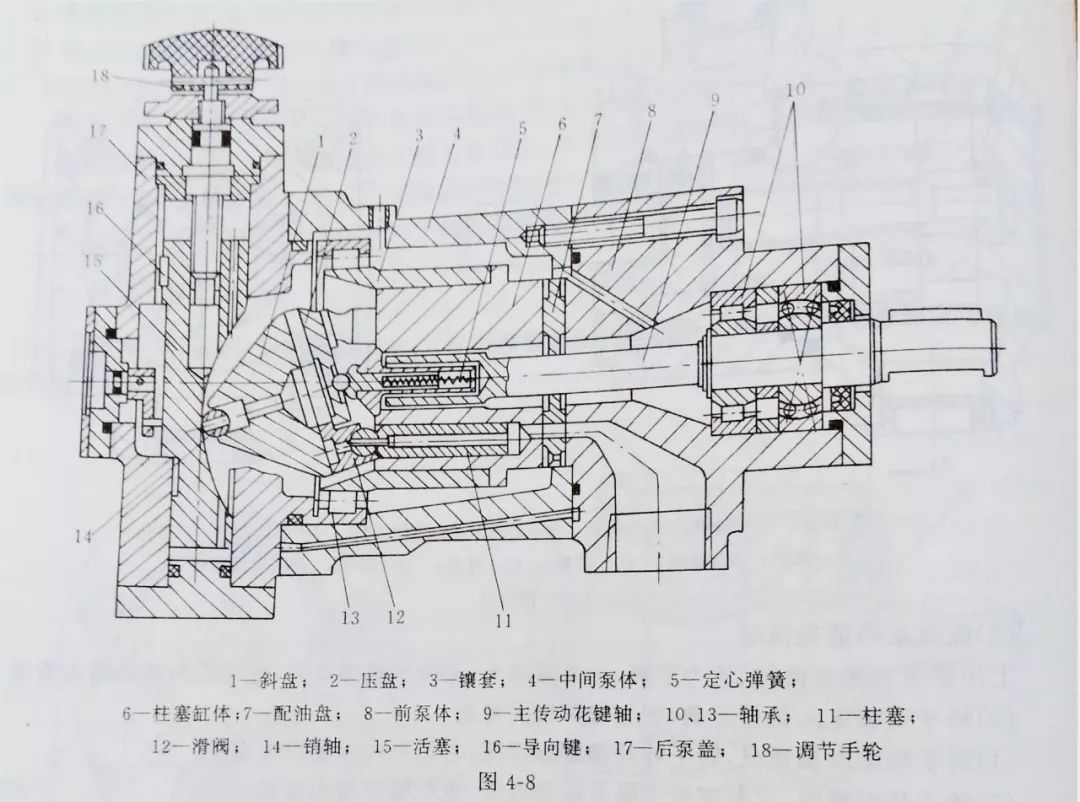

(11) Whether there are deposited wear debris or other contaminants inside the pump.Disassembly, Decomposition, Observation and Testing of Axial Piston Pumps. The structure of the SCY-type axial piston pump is shown in Figure 4-8. When disassembling and decomposing the axial piston pump, the following aspects of the pump can be inspected:

(1) Whether the distribution plate is worn or grooved.

(2) Whether the clearance between the plunger and the cylinder bore is too large.

The above situations are related to symptoms such as the decrease in pressure and flow, and the increase in internal leakage in the leakage oil pipe.

(3) Whether the central spring is weak or broken, which is related to the decrease in pressure and flow.

(4) Whether the damping holes of the plunger are blocked, which is related to the shrill sound emitted by the pump during operation when the slippers have dry friction.

(5) Whether the slippers and the plunger heads are loose, which is related to the increase in noise.

(6) The wear condition between the slippers and the swash plate, which is related to the heating of the pump and the increase in noise.

(7) Whether there are deposited wear debris and contaminants inside the pump.

Guangzhou NextGen Technology CO.,LTD

NextGen Tech, focusing on sealing technology, with excellent strength and reputation in the field of rubber and plastic seals, metal seals and mechanical equipment parts.

+86 172 7861 3980

Contact Information

Mob:+86 172 7861 3980

WhatsApp\WeChat:+86 172 7861 3980

Email:alfred@nextgen-tec.com

Add: No. 733 Huangpu East Road, Huangpu District, Guangzhou,Guangdong,China

Product Category