Mob/WhatsApp

.png)

+86 172 7861 3980

-

O-Ring

Material: EPDM

Color: Black,Brown, or as Your Request

Hardness: 30-90 Shore According to Work Environment

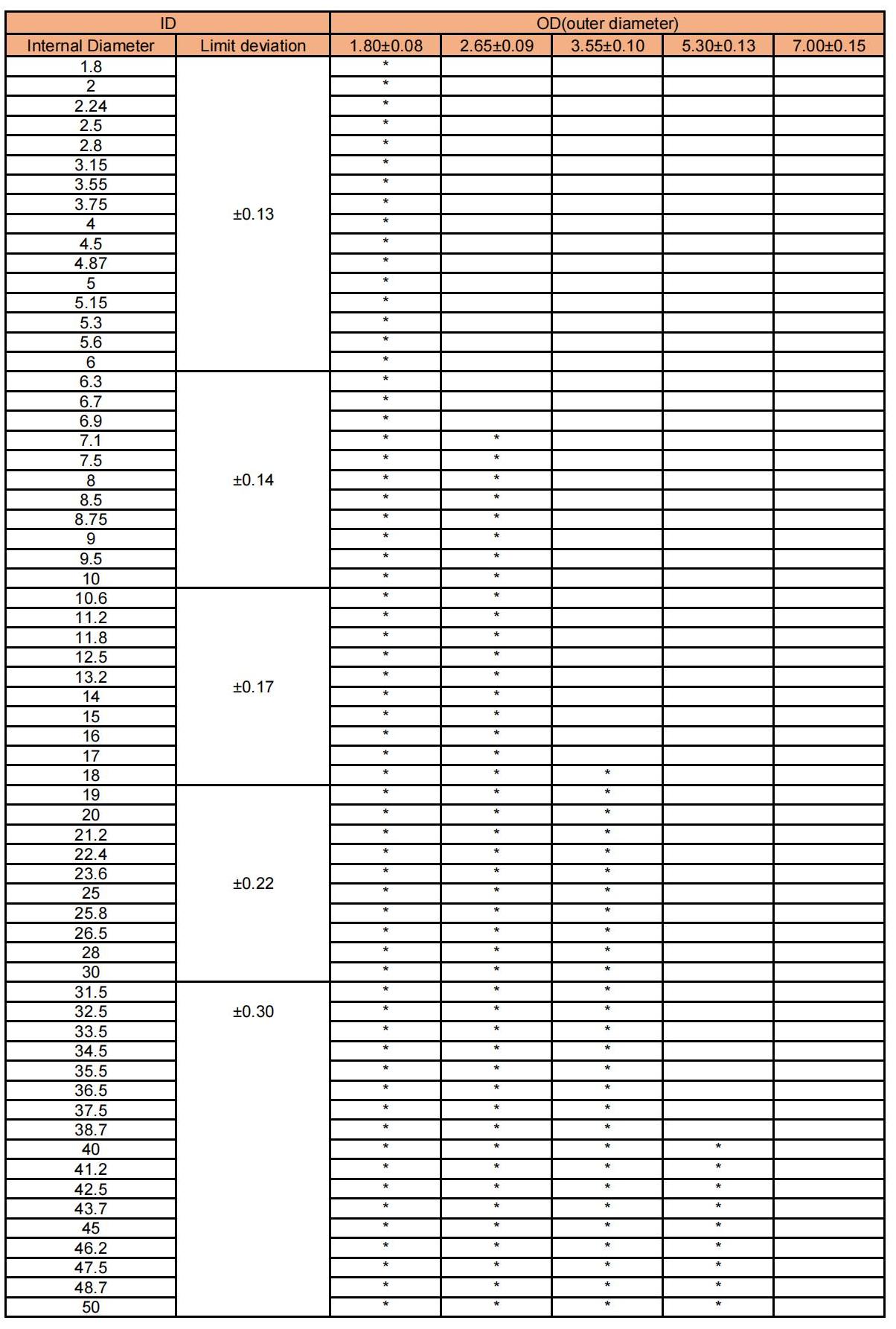

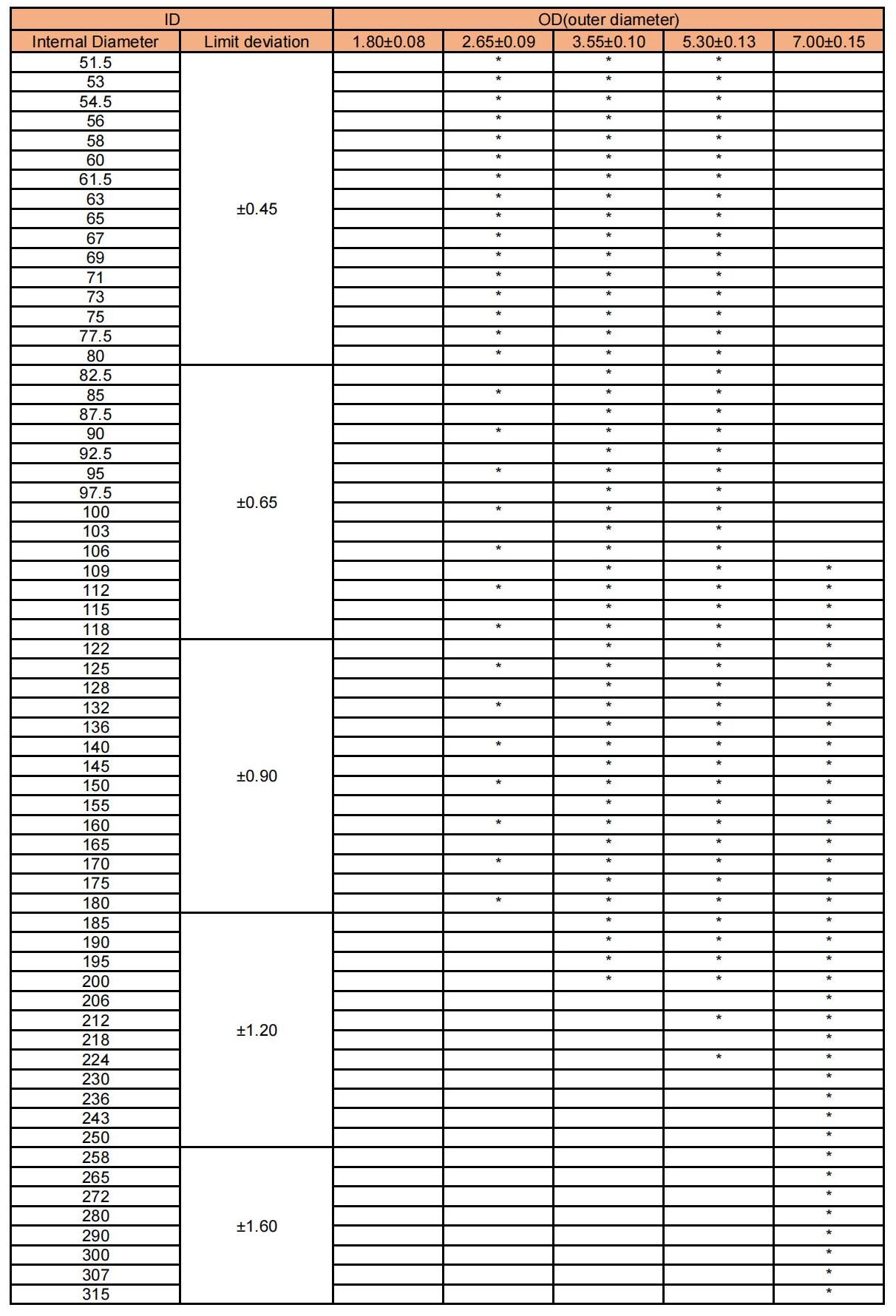

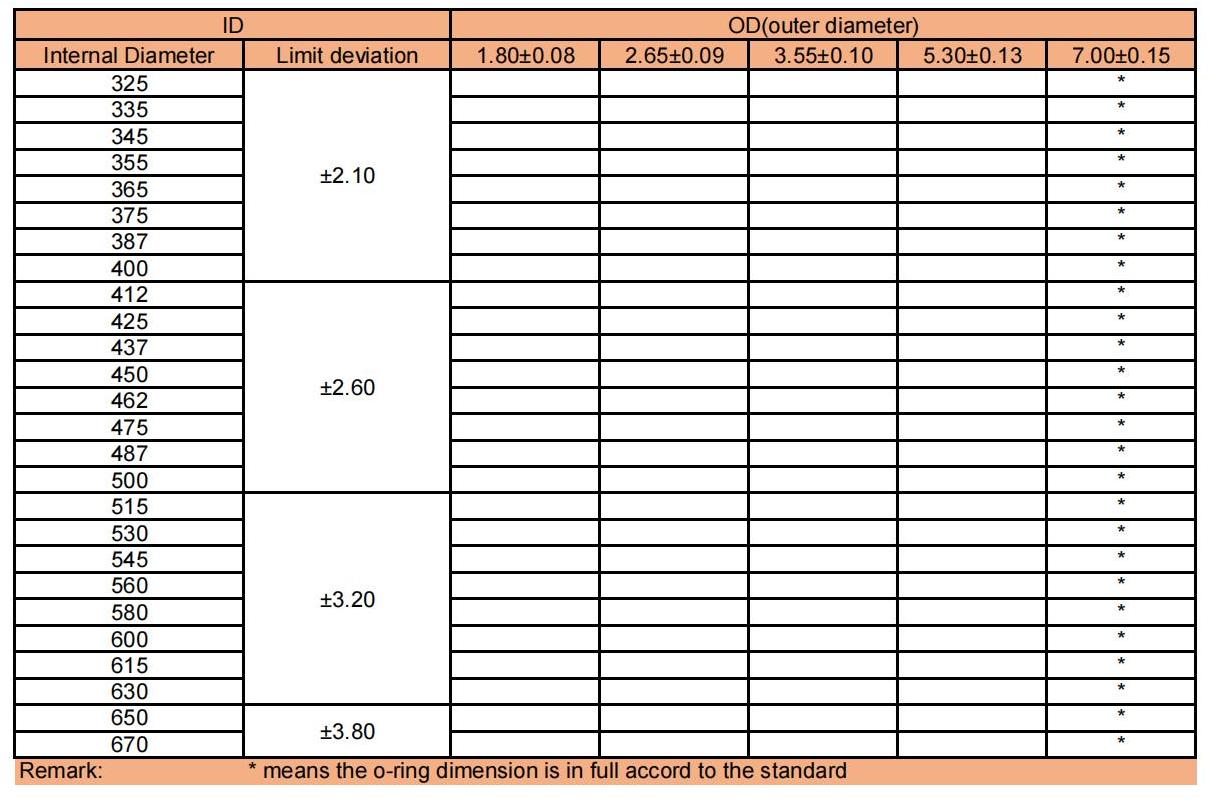

Specification: All STandard OD*ID*H, Customized-

0.000.00

-

Material: EPDM

Color: Black,Brown, or as Your Request

Hardness: 30-90 Shore According to Work Environment

Specification: All STandard OD*ID*H, Customized

Description

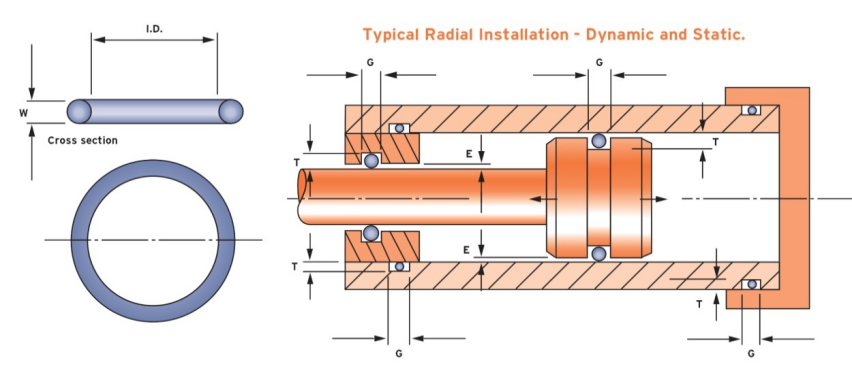

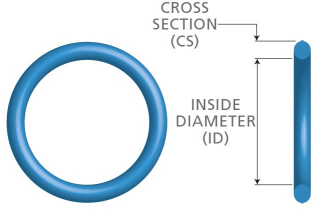

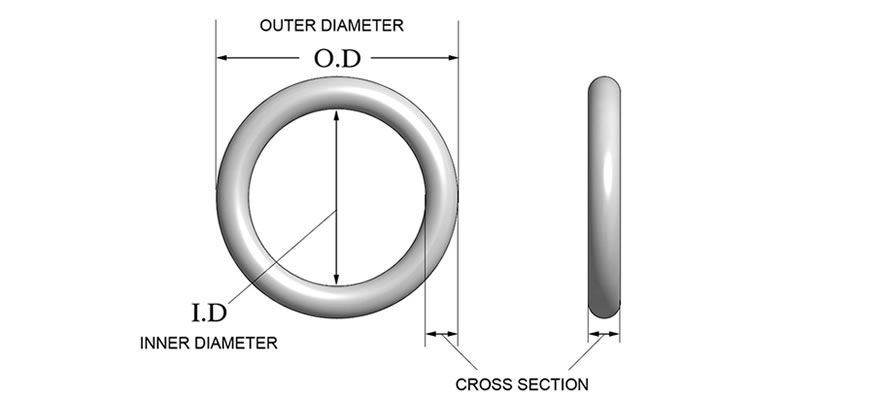

O-rings are circular sealing elements with circular cross-sections, may be used in static applications or in dynamic applications where there is relative motion between the parts and the O-ring. O-ring selection is based on chemical compatibility, application temperature, sealing pressure, lubrication requirements, durometer, size and cost. We offer you a range of elastomeric materials for both standard and special applications which allow the O-Ring to seal practically all liquid and gaseous media.

Design Theory

Orings are one of the most common yet important elements of machine design. They are available in various metric and standard sizes. Sizes are specified by the inside diameter and the cross section diameter (thickness). The most common standard sizes in the US are controlled by SAE AS568. ISO 3601-1:2012 contains the most commonly used standard sizes, both inch and metric, worldwide. The UK has standards sizes known as BS sizes, typically ranging from BS001 to BS932. In China, the standard for O ring is GB3452(new standard) and GB1235(old standard).The Japan also has standards sizes known as JIS standard(G series,P series). Several other size specifications also exist.O-rings can be produced by extrusion, injection molding, pressure molding or transfer molding.

Application

O-Rings are used in a variety of fields: they are either used as sealing elements or as energizing elements for hydraulic slipper seals and wipers. Thus, the O-Ring is basically used in every field of industry including aerospace, automotive or general engineering. Today, O-rings are one of the most common seals used in machine design because they are inexpensive, easy to make, and reliable and have simple mounting.

Features

All O Rings are made according to international standard: ISO 3601, AS 568, DIN 3771, JIS B2401, GB3452, BS1516.

Excellent abrasion and wear resistance

Excellent extrusion resistance, accepting even the most significant extrusion gaps

Very good mechanical properties

(1).jpg)

%201.jpg)

%202.jpg)

%203.jpg)

%204.jpg)

.jpg)

.jpg)

Service Hotline

+86 172 7861 3980

WhatsApp:+86 17278613980

mail:alfred@nextgen-tec.com

Add: No. 733 Huangpu East Road, Huangpu District, Guangzhou,Guangdong,China

Guangzhou NextGen Technology CO.,LTD

NextGen Tech, focusing on sealing technology, with excellent strength and reputation in the field of rubber and plastic seals, metal seals and mechanical equipment parts.

+86 172 7861 3980

Contact Information

Mob:+86 172 7861 3980

WhatsApp\WeChat:+86 172 7861 3980

Email:alfred@nextgen-tec.com

Add: No. 733 Huangpu East Road, Huangpu District, Guangzhou,Guangdong,China

Product Category