Mob/WhatsApp

.png)

+86 172 7861 3980

-

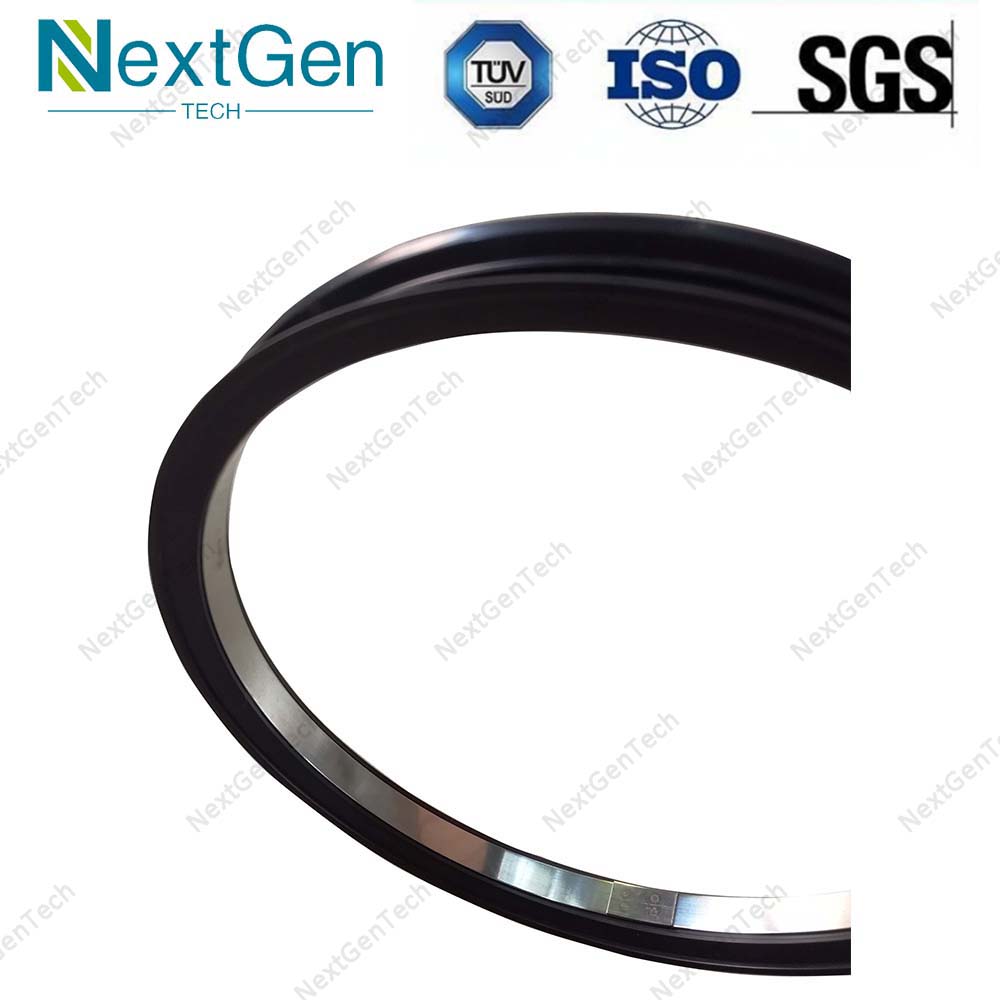

Rolling Mill Seal

Performance: Durable/Water Resistant, Oil Resistant/High Tempe

Shape:Rolling Mill Seal

Lip: Double Lips

Hardness: 80-85 Shore a

Pressure: 0.2-0.4MPa.

Working Medium: Hydraulic Oil, Water and Dust-

0.000.00

-

Performance: Durable/Water Resistant, Oil Resistant/High Tempe

Shape:Rolling Mill Seal

Lip: Double Lips

Hardness: 80-85 Shore a

Pressure: 0.2-0.4MPa.

Working Medium: Hydraulic Oil, Water and Dust

Description

Installation parts and functions

High-speed rotating parts of high-speed wire mill - pre-finishing mill stand, finishing mill adopts high-speed oil film bearings, its speed has reached 120~130m/s, representing the advanced level in this industry.

The oil film bearing is sealed with lip seals. Double lip seal is a key spare part for oil film bearings, which has two important roles: Seal the lubricating oil in the bearing chamber to ensure the formation of a continuous oil film. Seal the external cooling water, rolling oil, iron filings, dust and other debris, prevent infiltration into the bearing cavity, maintain the normal operation of the bearing.

If the seal fails, it will cause external cooling water, emulsion, iron filings and other impurities to invade the bearing, resulting in lubricating oil pollution in the bearing chamber, aging and consumption and waste of a large number of oil, and even cause bearing damage, shutdown accidents, affecting production, and economic losses are very large.

Sealing principle

When the rolling mill is working, the oil throwing ring rotates synchronously with the main shaft at high speed, and produces relative rotating motion with the two sealing lips. The sealing effect comes from two aspects: First, the contact stress of the sealing lip, the sealing lip and the oil throwing ring are compressed in the axial direction, the lip shrinks inward to form the interference amount, and the lip edge produces compressive stress to play a sealing role. Second, the oil swinging effect of the lip on the oil side of the seal will be thrown out of the oil on the lip edge at a high speed, making it return to the headstock to avoid a large amount of accumulation on the lip of the seal. Similarly, the water dumping effect of the lip on the water sealing side makes the water gather into the drainage system and discharge to the outside.

Service Hotline

+86 172 7861 3980

WhatsApp:+86 17278613980

mail:alfred@nextgen-tec.com

Add: No. 733 Huangpu East Road, Huangpu District, Guangzhou,Guangdong,China

Guangzhou NextGen Technology CO.,LTD

NextGen Tech, focusing on sealing technology, with excellent strength and reputation in the field of rubber and plastic seals, metal seals and mechanical equipment parts.

+86 172 7861 3980

Contact Information

Mob:+86 172 7861 3980

WhatsApp\WeChat:+86 172 7861 3980

Email:alfred@nextgen-tec.com

Add: No. 733 Huangpu East Road, Huangpu District, Guangzhou,Guangdong,China

Product Category